Grease Trap Installation

What is a Grease Trap?

Grease traps are passive devices required by local municipalities to stop grease, fat, oil, wax or debris from entering the city’s sanitary sewer system. Such materials cause

blockages in the system, which cause backups and overflows. They are designed to

separate grease from waste water so that it can be removed before it enters the sewer

system. All restaurants, caterers, school cafeterias and other commercial cooking

facilities must, by law, avoid discharging grease into the municipal sewer system. In

order to function properly grease traps must be pumped and cleaned on a regularly

scheduled basis.

Grease Trap Sizing Calculations

Please note that the following information is provided as a guide only, and is not to be used as a substitute for a professional evaluation of any business. A grease trap must be located at least 10 feet from hot water faucets. All hot water must cool to 120° F before entering the grease trap. The size of the grease trap must comply with the Uniform Plumbing Code. Any sink or disposal that can carry grease must empty into the grease trap.

Sizing a grease trap should always be left to a trained professional. This section is intended as a guide to familiarize the reader with some basic sizing rules. Requirements are determined by the volume of waste water that the grease trap can handle compared to demand. Unit selection depends on the type desired and its capacity rating in gpm. The Plumbing and Drainage Institute (PDI) defines standard sizes that are roughly equivalent to gpm of flow.

The National Plumbing Code lists drainage fixture-unit values of various plumbing fixtures based on drain outlet or trap size. These values are converted to gpm discharge rates assuming 7.5 gpm discharge to represent one fixture-unit. This information is illustrated below.The discharge rate will help to determine the model needed.

The National Plumbing Code lists drainage fixture-unit values of various plumbing fixtures based on drain outlet or trap size. These values are converted to gpm discharge rates assuming 7.5 gpm discharge to represent one fixture-unit. This information is illustrated below.The discharge rate will help to determine the model needed.

| Sizing Chart | ||||||

|---|---|---|---|---|---|---|

| Grease Trap / Outlet Size |

Fixture-Unit Value | GPM Equivalent | ||||

| 1 ¼” 1 ½” 2″ 2 ½” 3″ 5″ |

1 2 3 4 5 6 |

7.5 15.0 22.5 30.0 37.5 45.0 |

||||

To determine the size grease trap required, take the GPM equivalent for all the drains in the system and add them up. This will give you the required GPM for the entire system. For example, take a double sink with two 2″ drains. The sizing chart indicates that each of these drains will produce 22.5 gpm discharge, making the total requirement 45 gpm

The flow rate determines the grease trap model required.

For Sinks:

| Sink Size Interior Measurements |

# Bowls | Capacity in Gallons |

PDI SIZE (1 min.) |

PDI SIZE (2 min.) |

|

|---|---|---|---|---|---|

| 12″ x 18″ x 6″ 14″ x 16″ x 8″ 18″ x 20″ x 8″ 16″ x 18″ x 8″ 18″ x 20″ x 8″ 20″ x 30″ x 8″ 20″ x 24″ x 12″ 20″ x 22″ x 8″ 20″ x 22″ x 12″ 24″ x 24″ x 12″ |

1 1 1 2 2 1 1 2 2 2 |

4.2 5.8 9.4 15.0 18.7 15.5 18.7 23.0 34.0 44.9 |

7 7 10 15 20 20 20 25 35 50 |

4 4 7 10 10 10 10 15 20 25 |

|

* PDI = Plumbing and Drainage Institute standard size equivalent to gpm of flow |

|||||

Need your existing grease trap system jetted to keep it draining smoothly? We do that too! Check out our Hydro Jetting Services or call for a quote today! 1-800-905-7115

Why do I have to have a grease trap?

Fat Oil and Grease wreaks all kinds of havoc on municipal waste water systems, which is why local governments require commercial kitchens to have a grease trap installed. Most municipalities will have a minimum amount of FOG that is acceptable in the water leaving an establishment. IF these minimums are exceeded, fines can be imposed.

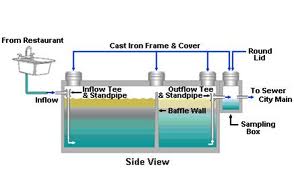

How does a grease trap work?

A grease trap slow down the flow of water coming from drains, allowing the water/ grease time to cool. This cooling causes the grease to coagulate and float to the top, while other, heavier solids, fall to the bottom of the trap. The remaining water is free to pass through on to the city sewer lines.

How do I maintain my grease trap?

Proper grease trap maintenance is very crucial in order to have an efficiently operating grease trap. Many problems can occur if the levels of collected FOG and solids are not monitored. Problems such as drain line blockages and back-ups, foul odors and even worse, too much FOG being deposited into the city sewer lines, which can lead to big fines.

Proper grease trap maintenance is very crucial in order to have an efficiently operating grease trap. Many problems can occur if the levels of collected FOG and solids are not monitored. Problems such as drain line blockages and back-ups, foul odors and even worse, too much FOG being deposited into the city sewer lines, which can lead to big fines.

Depending on the size, there are different ways of cleaning the grease trap. Many state and local governments have ordinances requiring that a grease trap be pumped out every so often, so it is important to first check with local government to find out this particular criteria. However, aside from any mandatory pump-outs that may be required, there are other methods of cleaning a grease trap that should be considered.

Many restaurants/ kitchens that have smaller grease traps often have their maintenance staff handle any grease trap maintenance. This could typically involve manually shoveling and vacuuming out the accumulated FOG and solids and disposing with the solid waste. It is important that if this is the step taken, any liquid waste be absorbed by an absorbent, like kitty litter, to ensure that the waste is picked up.

Most restaurants with larger grease traps will typically employ the services of professional recyclers/ haulers to pump-out and maintain the grease trap when the FOG accumulation gets too high. This is obviously easiest, but can be pretty costly especially if it is a weekly or monthly process.

The best grease trap maintenance routine that any restaurant or kitchen can implement to control the FOG build up and reduce the necessity of pump-outs is the use of a bacteria additive. Grease trap bacteria aids in the reduction of FOG and other organic waste by biologically breaking down and digesting the waste leaving behind only carbon dioxide and water. This can significantly reduce the need for frequent pump-outs along with controlling odors emitted by the grease trap. Additionally, as some of the bacteria are washed out with the water, it will serve to benefit the municipal waste water-receiving stream. Grease trap bacteria is available in varying types. Most common is probably the liquid form, which can be poured down the drains or applied directly to the trap. Another popular style is bacteria blocks, which are slow dissolve blocks that are suspended from a rope and submerged into the grease trap. Depending on the size of the block and grease trap, these blocks will last up to 4 weeks at a time. Powder varieties are also available and generally take up less shelf space and are cheaper to ship. Finally, grease traps can be set up with automatic injection pumps to automatically pump bacteria into the grease trap at set intervals for virtually maintenance free treatment.

In addition to keeping FOG minimized in the grease trap, bacteria can also serve to benefit drain lines in the kitchens as well. By mixing up a solution of the bacteria and pouring down all drain lines, the plumbing can be kept clear of FOG build-up that results in slow draining sinks and foul odors.

Other things to note to ensure good grease trap maintenance are to be sure and keep records of when maintenance procedures are done, such as pump outs, clean outs, when bacteria was added, etc. Also, staff should be encouraged to not just rinse everything down the drains. When possible, encourage the staff to throw solids and other waste in the trash. Do not hot rinse (hot flush) the drains and grease trap. This means running hot water through the lines to flush out any grease or other build up. This can prevent the grease from cooling in the trap and cause grease to be flushed into the sewer lines resulting in fines from the city. Finally, be weary of enzyme only products. There are many products on the market that are made up of enzymes and surfactants that simply liquefy the grease to get it out of the grease trap. All this does is cause more issues down stream at the waste water treatment level due to the eventual coagulation and solidification of this grease. It is for this reason that many municipalities are prohibiting the use of such products.

Contact us today for any of your grease trap needs or for a FREE estimate on your grease trap maintenance and repairs. 1-800-905-7115

We have a drain like that in our bensmeat that used to back up and flood our bensmeat lobby. We installed one of these but unfortunatly, sewage just poured out of the toilet and shower instead. Eventually we paid a33000 for a protective device to be installed on our main sewer pipe and havent had any touble since .expensive but the only way