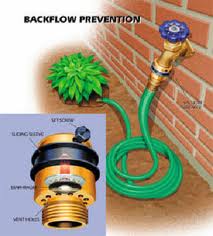

Back flow Prevention

A back flow prevention device is used to protect water supplies from contamination or pollution due to back flow.

Why is back flow prevention needed in a water supply system? Water is normally maintained at a significant pressure to enable water to flow from the tap, shower etc. When pressure fails or is reduced as may happen if a water main bursts, pipes freeze or there is unexpectedly high demand on the water system, the pressure in the pipe may be reduced and may allow contaminated water from the ground, from storage or from other sources to be drawn into the system.

Back Flow Prevention is also needed when back pressure is present. Back Pressure is another way that an undesirable contaminant may enter potable water piping. Sources of back pressure may be pumps in the water distribution system, boilers, heat exchanging equipment, or power washing equipment. In these cases there may be an almost constant risk of overcoming the static water pressure in the piping. To reduce the risk of contamination, a back flow prevention device can be fitted. A back flow prevention device is also important when chemicals are used, for instance for commercial/industrial descaling (boilers) or when bleaches are used for residential power washing.

To prevent cross contamination due to back pressure, some regulatory regimes require an air gap or mechanical back flow prevention assembly between the delivery point of mains water and local storage or use.Where submerged mains inflow is permitted a back flow prevention assembly is required, which protects the potable water system from contamination hazards. These hazards can be severe, and there are over 10,000 reported cases of back flow contamination each year. Some cases can be fatal. In many countries where regulations allow for the possibility of back flow, approved back flow prevention assemblies are required by law and must be installed in accordance with plumbing or building codes.

A typical back flow prevention assembly has test cocks and shut-off valves and must be tested each year, if relocated or repaired, and when installed.

In the United States, the Environmental Protection Agency (EPA) holds local water suppliers responsible for maintaining a certain amount of purity in potable water systems. Many states and/or local municipalities require annual testing of back flow prevention assemblies. A check valve is a common form of back flow prevention. In most cases, the law requires a double check (DC), an Reduced Pressure Principle Device(RP) device or an air gap when back flow prevention is mandated.

The simplest back flow prevention method, and the most effective way to provide back flow prevention is to provide an air gap. An air gap is simply a space between any device that opens to a plumbing system (like a valve or faucet) and any place where water can collect or pool.

Different types of Back flow Prevention Devices

Back flow Prevention using an Air Gap

An air gap, as it relates to the plumbing trade, is the unobstructed vertical space between the water outlet and the flood level of a fixture.

A simple example is the space between a wall mounted faucet and the sink rim (this space is the air gap). Water can easily flow from the faucet into the sink, but there is no way that water can flow from the sink into the faucet without modifying the system. This arrangement will prevent any contaminants in the sink from flowing into the potable water system by siphon-age and is the least expensive form of back flow prevention.

A common use of the term “air gap” in home plumbing refers to a fixture that provides back-flow prevention for an installed dishwasher. This “air gap” is seen above the counter top as a small cylindrical fixture mounted parallel with the faucet. Below the counter top, the drain pipe of the dishwasher feeds the “top” of the air gap, and the “bottom” of the air gap is plumbed into the sink drain below the basket. When installed and maintained properly, the air gap works as described above, and prevents drain water from the sink from backing up into the dishwasher, possibly contaminating dishes . Water flowing from the fixture into the sink indicates a need for maintenance or repair by a Scottsdale Plumbing Service .

To further illustrate the air gap, consider what could happen if the air gap were eliminated by attaching a hose to the faucet and lowering the hose into a sink full of contaminated water. Under the right conditions (if the water supply loses pressure and the sink is higher than the point at which the water supply enters the house, for instance), the dirty water in the sink will be siphoned into the water pipes through the hose and faucet. The dirty water then will be dispersed throughout the drinking water system.

All plumbing codes require back flow prevention in several ways. The plumbing fixture manufacturers build the fixtures to meet these codes. A Scottsdale plumber must not build cross-connections in his daily work practices, and Plumbing Inspectors look for improper designs or connections of piping and plumbing fixtures. A common misconception is that a “high loop” (routing a drain line above a sink’s flood level, for instance) will provide the same function as an air gap; this is not true, because the continuous connection in such a case still will allow back flow through siphoning.

An air gap must meet the requirements of being two times the effective inner diameter of the pipe (2*D) in order to be sufficient.

Back flow Prevention using a Pressure Vacuum Breaker

A Pressure Vacuum Breaker (PVB) is a type of back flow prevention device, used to keep non-potable (or contaminated) water from entering the water supply. A PVB is similar to an atmospheric vacuum breaker (AVB), except that the PVB contains a spring-loaded poppet. This makes it acceptable for applications that are high hazard or where valves are downstream. Pressure vacuum breakers must be protected from freezing when installed outdoors. PVBs usually have test cocks, to which specially-calibrated gauges are attached, in order to ensure that the back flow prevention device is functioning properly.

Back flow Prevention Devices are manufactured by Watts, Febco, Zurn and other manufacturers. Back flow prevention devices such as PVBs are regulated by the Uniform Plumbing Code, but may also be required by government regulations.

Double Check Valve

A double check valve or double check assembly (DCA) is a back flow prevention device designed to protect water supplies from contamination.

Usage in Water Supply: In the case of usage in water supply, it consists of two check valves assembled in series. This employs two operating principles: firstly one check valve will still act, even if the other is jammed wide open. Secondly the closure of one valve reduces the pressure differential across the other, allowing a more reliable seal and avoiding even minor leakage. Back Flow Prevention Devices must be tested to ensure that there is no possibility of cross contamination

Small valves may be so compact as to be barely noticeable, particularly when they are integrated into the bodies of existing taps (faucets). Larger check valves may be installed with ball valves at the ends, for isolation and testing. Often, test cocks (very small ball valves) are in place to attach test equipment for evaluating whether the double check assembly is still functional.

The double check valve assembly is suitable for prevention of back pressure and back siphon age, but is not suitable for high hazard applications. It is commonly used on lawn irrigation, fire sprinkler and combination boiler systems. If the hazard is higher, even a relatively low hazard such as using antifreeze in the fire sprinkler system, then a more reliable check valve such as a Reduced pressure zone device may be mandated.

Call your Plumber In Scottsdale today for all your Back Flow Prevention Device needs.

1-800-905-7115

Whoa what was that? Oh.. It was Swabbie throwing the BS Flag again. First.. you CANNOT just start a Plumbing business, you must be licensed.. for that you must have completed Journeyman training with a REAL Plumber. Each state has it’s own licensing details.. Then the other reason that flag went flying is that.. IF you have to ask what tools you need.. that means you have no earthly idea of even how to sweat a fitting or even what that term means.Next time get a little more creative..